CANOLA OIL PROCESSING

We manufacture the complete line for canola processing

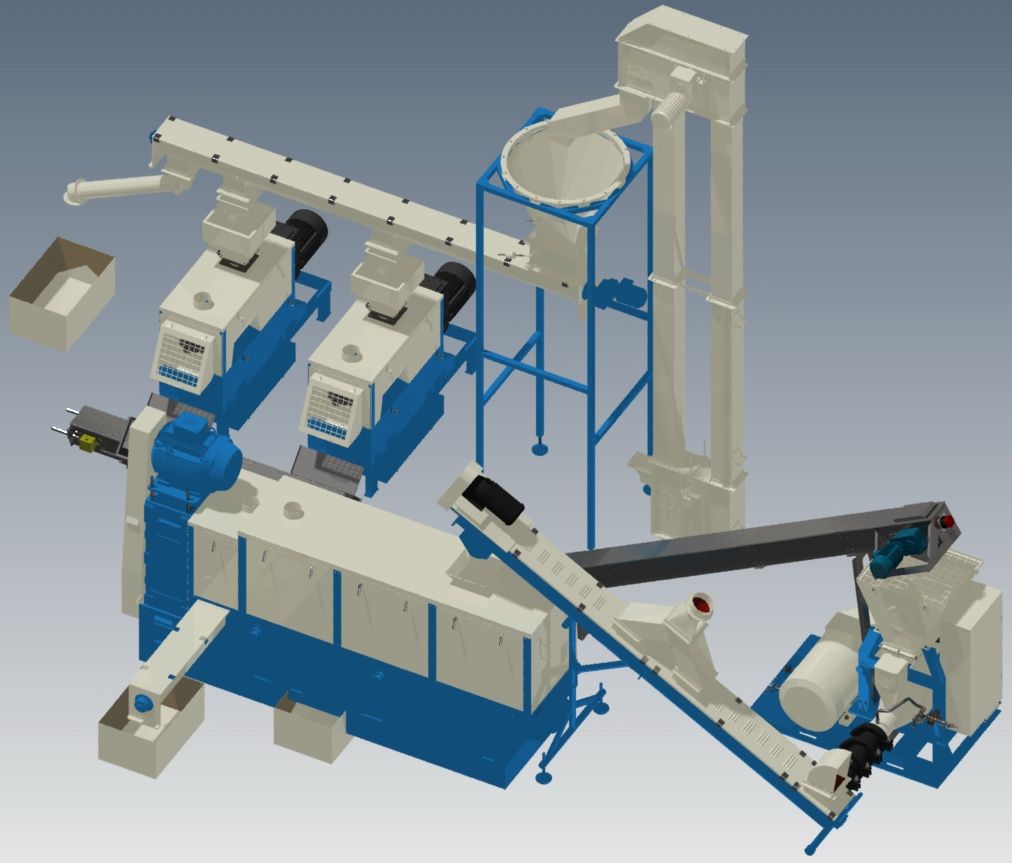

VIDEO: CANOLA PROCESSING LINE

About the processing line:

For the line installation you need the territory of 500 ... 800 m2

The rapeseed prior processing should be cleaned and dried up to 7 ... 9%.

After the oil cake has been discharged, it preferably goes to floor storage, with no packaging. Usually, our customers load the ready oil cake into motor transport and take it further according to the technology to feed manufacturing plants.

Canola oil accumulates in storage tanks; there is no refining function.

Installation of the line and connection to the power grid is done by the customer according to the scheme. We carry out start up and adjustment of the line.

The warranty on equipment is 12 months with post-warranty service.

The line consists of:

- Grain heater GH -1000

APPLICATION:

is used to preheat the grain feedstock up to 15-20°С. It could be used in the cold season so that the processes of extrusion and oil pressing proceed more efficiently.

ADVANTAGES:

• increases oil yield at the first cold extraction

RAW MATERIAL:

canola seeds

POWER: 24 kW

- OIL PRESS RP-500

APPLICATION:

Preliminary or pre-pressing from canola seeds

We use 2 preliminary oil presses RP-500 in our line.

The product is moved along the press cage being squeezed and pressed again. Under pressure the oil seeps out through the press cage gaps and gathers into the oil reservoir below.

Final oil content in the ready oil cake after it has been discharged: 22 ... 25%

Temperature of oil pressing: 55 ... 60°С

POWER: 2*22 kW

- EXTRUDER E-1000

APPLICATION:

inside the extruder barrel canola oil cake is compressed, mixed and heated which helps to increase the final oil yield

FINAL PRODUCT:

- canola oil cake heated up to 110 ... 130 °С

RAW MATERIAL:

- semi fat canola oil cake

POWER: 92 kW

- OIL PRESS RP-1000

APPLICATION

for oil cake with oil content up to 9%

FINAL PRODUCT:

- canola oil

- canola oil cake (with oil content 7 ... 9%)

RAW MATERIAL:

- heated semi fat canola oil cake

The product is moved along the press cage being squeezed and pressed again. Under pressure the oil seeps out through the press cage gaps and gathers into the oil reservoir below.

Semi fat oil cake is moved into the cooler.

POWER: 45,6 kW

- COOLER ОЕ-1000

APPLICATION

for cooling down the bulk products right after extrusion or oil pressing

FINAL PRODUCT:

canola oil cake with temperature 10-15 degrees higher than the temperature in the shop

RAW MATERIAL:

hot oil cake (with temperature of 130 °С) or other bulk products

POWER: 4.5 kW

- TRENCH CONVEYOR KTC-30

APPLICATION

for handling grain or other bulk materials from grain dump pit, storage hopper or trucks

ADVANTAGES:

• moves the products at a distance of 13 m horizontally and 4 m vertically

• reduces the depth of the grain dump pit

RAW MATERIAL:

grain, cereals, flour, bran with a specific weight 250-850 kg/m³

POWER: 2.2 kW

- SCREW CONVEYOR SF-250

APPLICATION:

for handling bulk products between processing equipment

steam removing

ADVANTAGES:

• nozzles for steam removing

• perforated upper cover

• not secured to the floor

RAW MATERIAL:

full-fat soy, oil cake, grain, cereals, flour, sawdust, hulls and other bulk materials with a specific weight of 150-850 kg / m³

POWER: 1.1 kW