MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

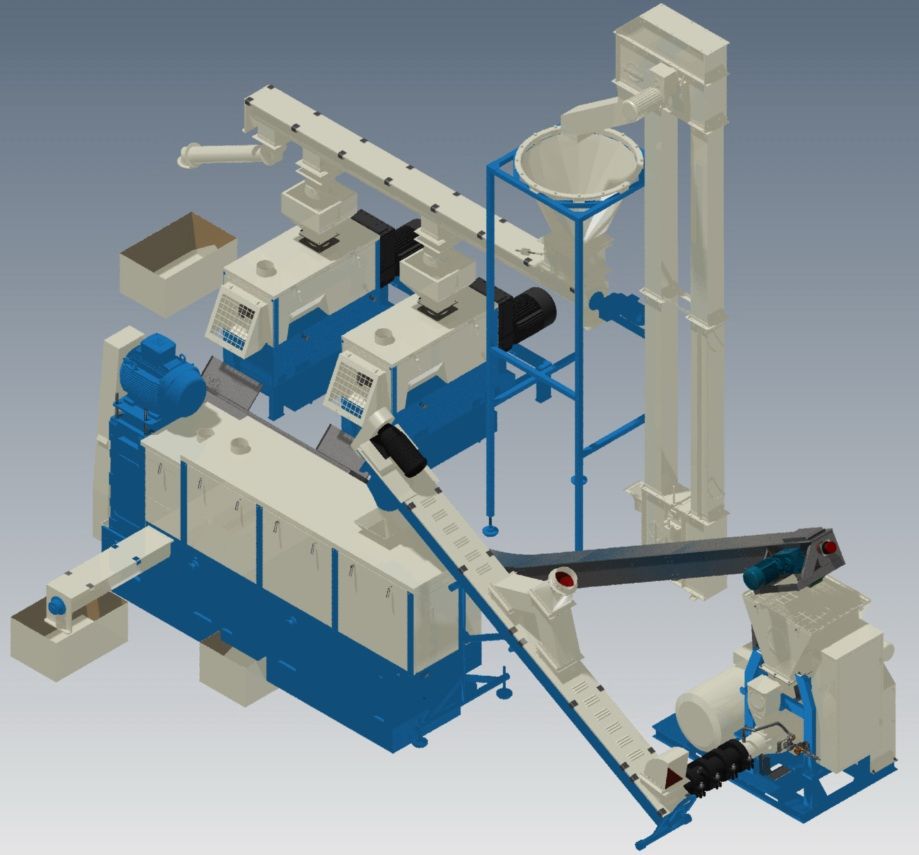

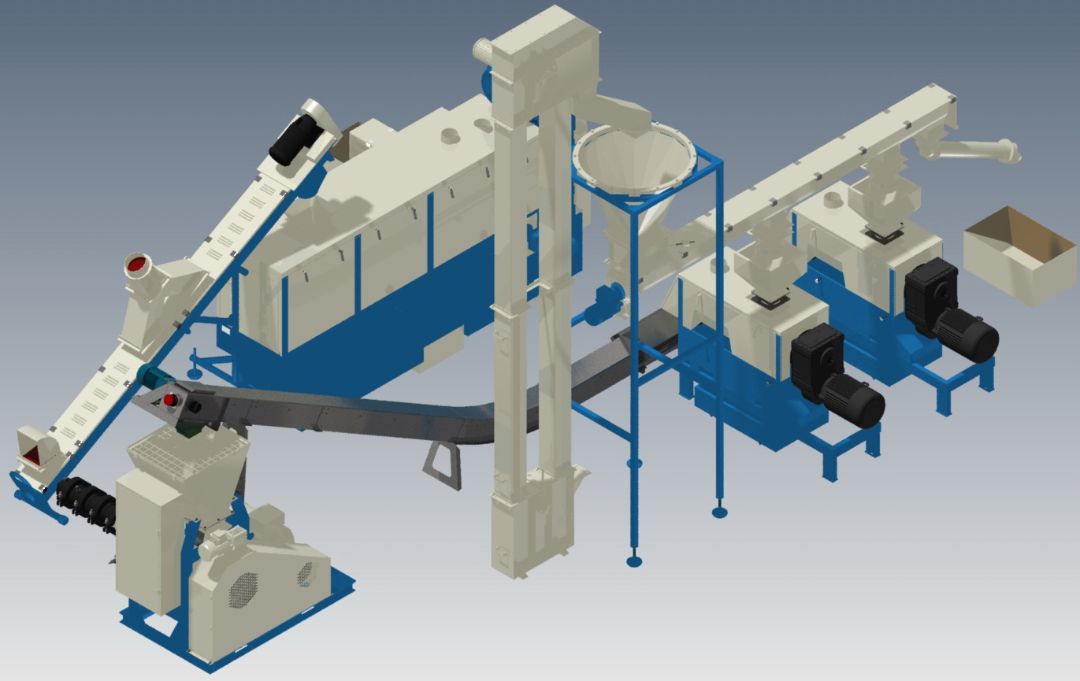

RP-1000:

CherkasyElevatorMash Ltd TM BRONTO

FINAL PRODUCT: CANOLA CAKE

RAW MATERIALS: canola cake (after the first extraction of oil)

humidity: 8 ... 12%

TECHNICAL SPECIFICATIONS:

Productivity: 1000 kg / hour

Oilcake of oilcake: 07 ... 10%

Oil content of raw materials: 22 ... 26%

Humidity of raw materials: 6 ... 7%

Length: 3970 mm

Width: 960 mm

Height: 2200 mm

Weight: 6950 kg

POWER: 45.6 kW

ADVANTAGES:

SEQUENCE OF OIL PRESS MACHINE OPERATION:

Quality assurance:

Warranty period is 1 year